Disc Disperser

(with Double Hydraulic Cylinder Drive)

Disc Disperser

(with Double Hydraulic Cylinder Drive)

Application

The ZDR series disc disperser comes with double hydraulic cylinder drive. It is used for handling the impurities in waste paper, such as hot melt material, adhesive material, asphalt and ink etc.

Under the conditions of high temperature and high consistency, the visible fine impurities, which cannot be removed in the preceding procedure, will be intensively peeled off and dispersed into invisible tiny granules by the fibrillating fluted disc whose control accuracy is 0.01mm. And by fibrillating fibers, pulp's beating degree, paper sheet's formation and breaking length can be improved by intensifying the even mixture of bleaching chemicals with pulp.

Features

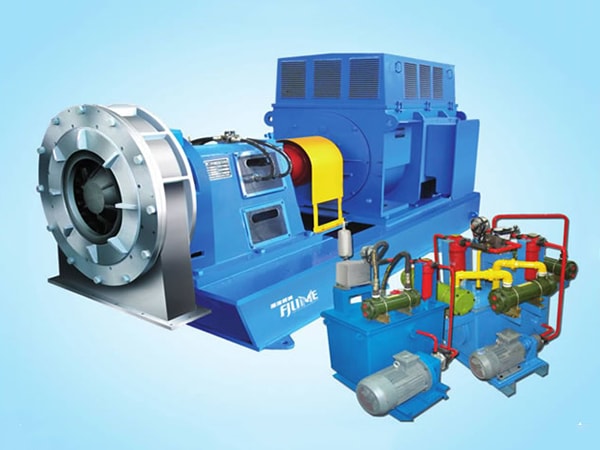

- The disc disperser consists of fibrillating fluted disperser, machine body, driving unit, main control hydraulic system, displacement sensing unit and lubricating system, etc.

- In the heating screw, the pulp with the consistency of 25~30% is heated to 80~130℃ and mixed with the chemicals. Then the pulp enters the feeding screw in the form of round particles. Through the screw-rotating disc in the heat dispersing system, the pulp is extruded into the 0.1~0.5mm gap between the fibrillating fluted moving disc and fixing one, and then outwards from the center the pulp goes through the crushing, jordaning and refining zones between the fluted discs. Between the fibrillating fluted discs, the pulp will be mechanically and physically acted intensively and evenly, rubbed and softened so that the hot melt material, adhesive material, ink and others will be peeled off from fibers and dispersed into invisible tiny granules and the pulp will be mixed with the chemicals evenly.

- Inside the disc disperser, main control hydraulic system, position sensitive device and electrical system implement automatic detection of the gap of the fibrillating fluted discs with the control accuracy of 0.01mm, which makes the gap come back to the normal value so that the technical performances of the dispersion machine will be assured.

- Dispersing specific energy is controlled by the electrical-hydraulic system with the accuracy of 0.01mm, so that the best stability of quality will be ensured.

- This disc disperser helps in improving the process properties of fiber and enhancing the strengths of pulp. After treatment, the pulp is visually even. This pulp machine helps in significantly reducing power consumption to 35~40KW/h per ton of pulp.

Specifications

| Model | ZDR22 | ZDR23 | ZDR24 |

| Capacity (t/24h) | 20~60 | 80~250 | 150~400 |

| Disc Diameter (mm) | Φ500 | Φ710 | Φ1050 |

| Working Consistency (%) | 25~30 | ||

| Working Temperature ( ℃ ) | 80~130 | ||

| Disc Drive Method | With Double Hydraulic Cylinder Drive | ||

| Disc Rotation Speed (rpm) | 1485 | ||

| Motor Power (KW) | 110~200 | 200~630 | 710~2000 |

Related Products

Get in Touch