Batch Displacement Cooking System (BDC)

Batch Displacement Cooking System (BDC)

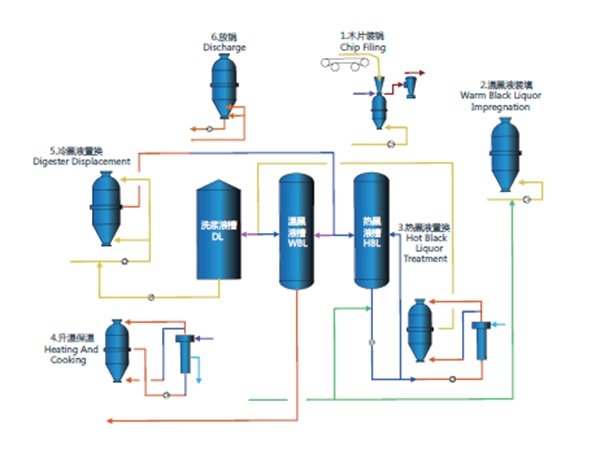

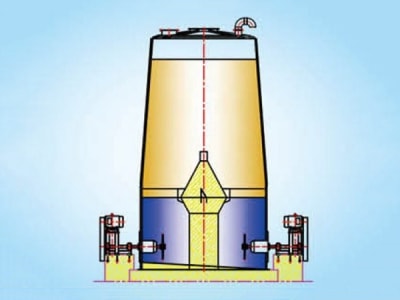

Featuring energy-saving and emission reduction, BDC batch displacement cooking is an extended delignification process used in chemical pulp mills. A displacement cooking system can be equipped with 1-5 digesters, 2 pressure liquid recovery accumulators and several ordinary pressure tanks. In addition to the batch replacement operation, there are other continuous operations, such as: heat transfer within tank zone, fiber separation, condensate water treatment and gas collection. This cooking system is suitable for non-woody fibers including wood chips, bamboos, straws and others.

How it works?

- Chip filling: The chips are put into the digester, at the same time, the air is evacuated from digester.

- Black liquor impregnation: fill the digester with black liquor from black liquor tank and add appropriate white liquor.

- Hot black liquor replacement: fill the digester with hot black liquor and white liquor to replace warm black liquor in the digester.

- Heating and cooking: steam heats digester to the maximum cooking temperature and keep the temperature.

- Cold black liquor replacement: fill digester with cold black liquor to replace the hot black liquor, cooling the pulp.

- Discharge: send cooling pulp to blow tank.

Features

- Saves steam and reduces energy consumption (0.75 - 1.3 tons of steam / pulp)

- Good pulp strength, improved yield

- Reduces the consumption of bleaching chemicals and the pollution of waste water

- Decreases the viscosity of black liquor, which is conducive to evaporation

- The replacement of black liquor is equivalent to one-stage pulp washing.

- The cooking time is shortened, greatly improving the cooking efficiency.

- Eliminates cooking odor, and reduces wastewater discharge, providing outstanding environmental benefits.

- Comes with automatic control of the whole production process, and stable system operation.

Related Products

Get in Touch