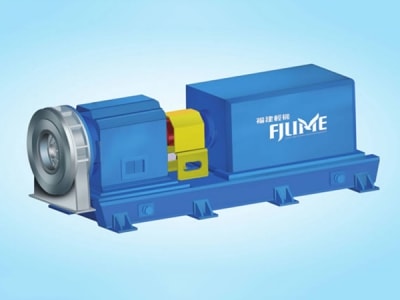

Coarse Screen (Medium Consistency), ZSN Series

Coarse Screen (Medium Consistency), ZSN Series

The ZSN series medium consistency coarse screen has the feature of good adaptability with high production capacity. With high flow speed, it can offer high production efficiency. It is exceptionally suitable to be as coarse screen for recycling waste paper. The advantage of M.C. Coarse screen is to adopt the new design of sword-shaped rotor for saving energy. The new rotor structure is developed with application of fluid dynamics theory.

3D structure of rotor blades strengthens turbulence inside screen to promote rejects discharging efficiency, as well as to avoid pulp thickening. It also slows down linear speed of rotor to achieve high capacity. With the help of corrugated screen basket which aims at better performance and high throughput, the screen upflow design can save 30-60% power consumption and improve screening efficiency.

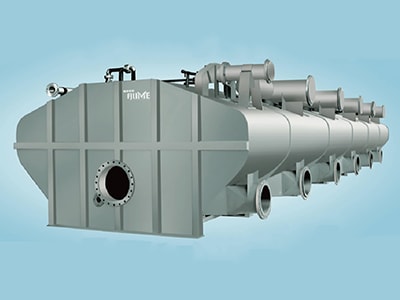

- The coarse screen (medium consistency) combines cleaning and screening together. The stock enters the vat from the bottom. Then the stock is revolved by the drum and the heavy impurities will be instantly discharged from the outlet.

- The rotor of the pulp screen machine in accepts side enables accepts to pass the screen plate with less resistance, resulting in higher throughput.

- The machine can discharge heavy impurities continuously and intermittently, and discharge light impurities continuously.

- The coarse screen (medium consistency) is of simple structure and easy operation and can be used as fiber separator.

| Model | Screen Area (㎡) | Inlet Consistency (%) | Inlet Pressure (MPa) | Screen Hole Size (mm) | Capacity (t/24h) | Motor Power (KW) |

ZSN61 | 0.5 | 1.2-3.5% | 0.15-0.3 | 1.2~2.5 | 15~40 | 18.5-45 |

ZSN62 | 1.0 | 30-80 | 45-90 | |||

ZSN63 | 1.5 | 45-120 | 55-110 | |||

ZSN64 | 2 | 60-160 | 75-160 | |||

ZSN65 | 2.5 | 75-200 | 90-200 | |||

ZSN66 | 3 | 90-240 | 110-250 | |||

ZSN67 | 4 | 120-320 | 160-315 |