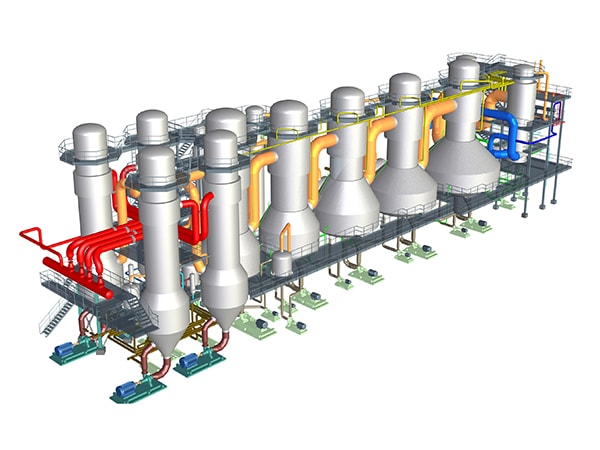

Tube Type Falling Film Evaporator (TFFE)

Tube Type Falling Film Evaporator (TFFE)

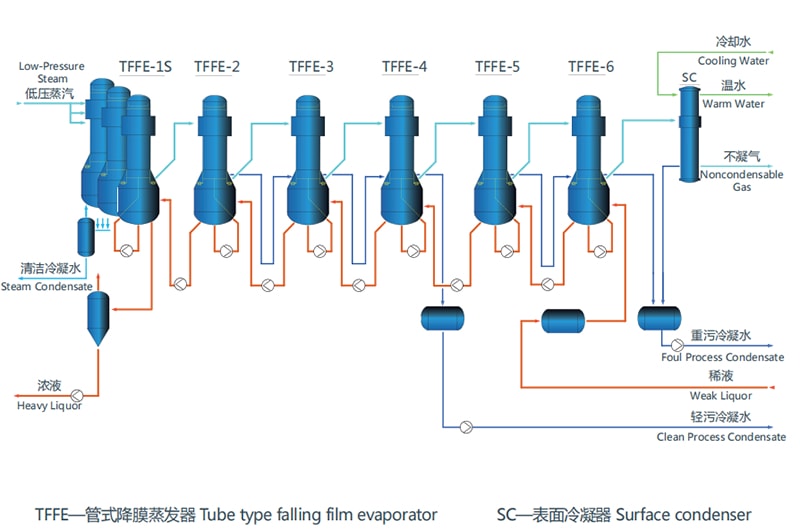

Tube type falling film evaporator is made up of the heating chamber, distribution tray, separation chamber, mist eliminator, recirculation pipe, support legs, etc. Heating chamber is constructed with tube plates, heating tubes, baffles, shell, etc.

Black Liquor Concentration

- Black liquor from wheat straw pulp: 43%-60%

- Black liquor from reed pulp: 48%-60%

- Black liquor from bamboo pulp: ≤70%

- Black liquor from wood pulp: ≤80%

Industries Served

- Black liquor evaporation and concentration in the pulp and paper industry

- Alkali liquor evaporation in the metallurgical alumina industry

- Evaporation and concentration of materials in the food and pharmaceutical industry

- Evaporation and concentration in the process of seawater desalination

- Evaporation and concentration of chemical products in the chemical industry

Features

- Heat Transfer Coefficient

Some advantages of falling film design are related to the circulation volume, the heat transfer mechanism and vapor release. High heat transfer coefficient of tube falling film evaporator results from:

1) Both gravity and vapor velocity accelerates the falling liquor flow as it travels along the tubes.

2) Condensates that travel along the tubes are truncated by the evaporator baffle, resulting in thinner condensate film and reduced thermal resistance.

3) The wall thickness of the heating tubes can be designed to be thinner, thus reducing the thermal resistance. - High Strength, Long Service Life

The tube type design of our falling film evaporator offers substantially less welding and stressed areas than the plate type design, resulting in reduced risk of stress corrosion and of preferential attack at the welds. The TFFE design used in all FJLIME evaporators provides superior strength, long life and excellent reliability in performance. - Built-in Recirculation Piping

TFFE recirculation piping is equipped in the interior of the evaporation equipment. The advantage of this design is its simplicity in terms of piping, control and maintenance. The recirculation piping is minimized as it consists of a downcomer from the separation chamber to the recirculation pump and then a return pipe back to the preheating section. In addition to reduced capital costs, the PF evaporator minimizes heat dissipation and pump head requirements through the recirculation piping. - Open Distributor

Flow distribution is important in a falling film evaporator. TFFE includes an opening distribution tray, which is very tolerant to suspended solids and fibre, and the tube bridge distribution is formed by the heating tubes and its three corresponding liquid distribution holes, making Liquor distribution more uniform. - High Efficiency Mist Eliminator

Mist eliminator in falling film evaporator is an important element, which decides the COD (Chemical Oxygen Demand) value of the process condensate. The demisting efficiency of FJLIME’s demister is high, which makes the process condensate color clear, low COD value. The process condensate return usage rate is highly improved, significantly reducing contaminated water of mills.

Related Products

Get in Touch