The wet lap or pulp baling system is used for the treatment of paper pulp with dryness of approximately 35% to 55%. For short-distance convenient transportation, the liquid paper pulp is dehydrated into wet pulp by a thickener or pulp extruder so as to formulate wet lap for use in our factory or the nearby paper factory without pulping system.

This production line is suitable for production of various raw materials such as mechanical pulp, chemical mechanical pulp, bamboo pulp, waste paper pulp and more. After all stages of dehydration, the wet lap machine can achieve the pulp consistency, also called final dryness of wet lap, ranging from 28% to 48%. The final material will be directly sent to the wet lap baling system.

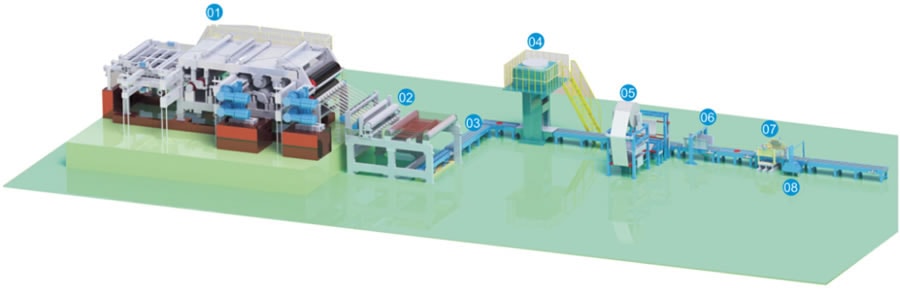

This wet lap baling line is mainly composed of the double-wire wet pulp press, wet lap cutting machine, chain conveyor, vertical hydraulic press, packing machine, ink-jet printer, folding machine and strapping machine.

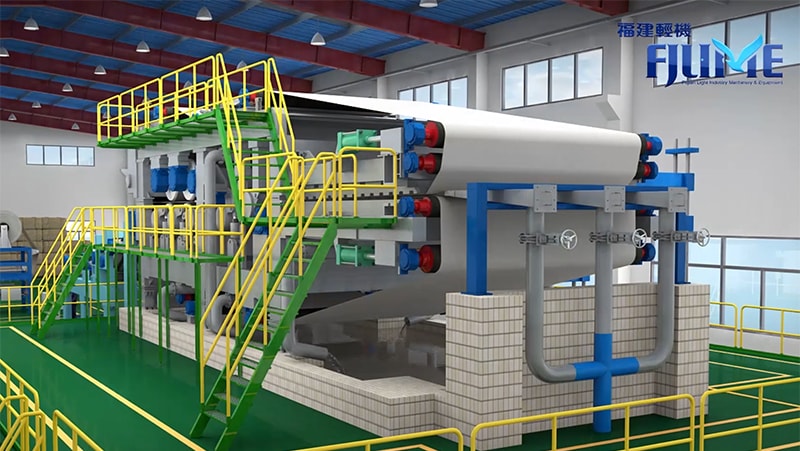

- Six-Nip Double-Wire Wet Pulp Press

- Layboy / Cutting Machine

- Chain Conveyor

- Vertical Hydraulic Press

- Packing Machine

- Ink-Jet Printer

- Folding Machine

- Strapping Machine