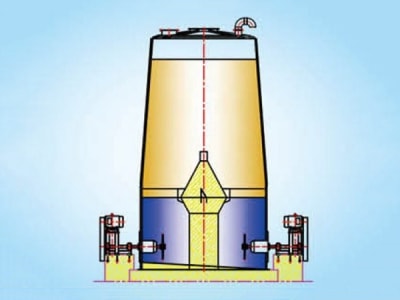

Disc Thickener

Disc Thickener

ZNP series disc thickener is designed for washing and thickening low consistency pulp in the waste paper recycling and papermaking industries.

- Disc thickener is compact and efficient.

- The disc sector is welded by stainless steel so that it has good resistance to corrosion and is easy to take apart.

- Large filtering area allows this pulp thickener to filter large amount of white water. The density of the filtered water is relatively lower than the water filtered by drum thickener.

- With reliable quality, our disc thickener is successfully exported to many countries including Peru and Ecuador.

The disc thickener works on the principle of dewatering by gravity through the level difference between the stock outside the filter net and the white water in the disc. When the stock with the consistency ranging from 0.8 to 1.2 percent enters the stock vat, it is instantly adsorbed to the disk sector. The water in the disk flows to the ends of hollow shaft through guide slot and then is discharged. The stock attached on the disc will be washed away by high pressure water. When the stock level is higher than the adjusting valve, the stock will flow to the stock vat and then be discharged. The outlet consistency ranges from 3 to 4%. The rotating speed of main shaft can be adjusted according to the required outlet consistency and production capacity.

| Model | ZNP1 | ZNP2 | ZNP3 | ZNP4 | ZNP5 | ZNP6 | ZNP7 | |

| Plate Dia(mm) | 2500 | 2500 | 2500 | 3500 | 3500 | 3500 | 3500 | |

| Inlet Consistency(%) | 0.8~1.2 | |||||||

| Outlet Consistency(%) | 3~4 | |||||||

| Water Pressure(MPa) | 0.4~0.6 | |||||||

| Screening Area(m2) | 40 | 60 | 90 | 120 | 150 | 180 | 240 | |

| Stainless Steel Wire Number | 35/40 | |||||||

| Capacity (t/d) | OCC | 80~100 | 120~150 | 180~200 | 240~260 | 300~320 | 360~380 | 400~500 |

| ONP | 40~50 | 60~75 | 90~100 | 120~130 | 150~160 | 180~190 | 240~250 | |

| Motor Power(KW) | 11 | 11 | 15 | 22 | 30 | 30 | 37 | |

| Plate Number(n) | 6 | 8 | 12 | 8 | 10 | 12 | 16 | |