H.C. Pulper

H.C. Pulper

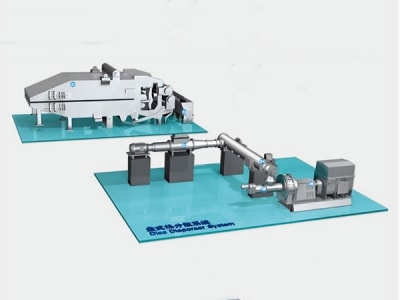

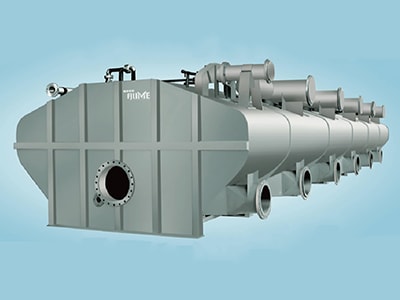

H.C. Pulper can pulp waste paper at a consistency of 10 to 15%. Compared with low consistency pulper, the machine uses 25 to 30% less energy. It can also save power by 50% and chemicals by 20% during operation.

When the H.C. Pulper pulps compound waste paper with many impurities, such as plastics, metals and wood, it won't crush these impurities. In this way, it can facilitate the purification in the subsequent process.

With compact structure, easy operation and reliable quality, this pulping machine is highly recognized by customers from various countries such as Peru and Indonesia.

H.C. Pulper is widely used in waste paper deinking. Under a consistency of 15 to 17% and the effect of physical force and chemical force, the machine can disintegrate white waste paper, such as newspaper, magazines, and compound paper, into fibers and effectively separate the fibers from impurities such as ink and plastics. This pulping equipment is mainly applied in waste paper recycling and paper making industries.

H.C. Pulper is composed of main parts like steel vat, vertical helical rotor, drive mechanism and discharging device.

The rotor is a three-thread helical rotor with variable pitch and diameter. When the rotor rotates, the stock at a consistency of 15 to17% flows by the helical force in the direction from top to the bottom, outside to inside, and center to periphery. The intensified axial flow of stock makes the fibers rub against each other as well as the spiral wing. In this way, waste paper stock is fiberized, and in the meantime, the ink comes off the fibers.

| Model | Capacity (t/24h) | Effective Volume (m³) | Rotor Diameter (mm) | Rotor Type | Stock Consistency (%) | Hole Size (mm) | Motor Power (KW) | ||

| ONP | OCC | ONP | OCC | ||||||

ZDS41 | 4 ~ 10 | 1 | Φ 480 | 3-Thread Helical Rotor with Varied Pitch and Varied Diameter | 15 ~ 17 | 10 ~ 12 | Φ10 ~ 12 | Φ16 | 22 |

ZDS42 | 8 ~ 24 | 2.5 | Φ 740 | 55 | |||||

ZDS43 | 15 ~ 45 | 5 | Φ 920 | 110 | |||||

ZDS44C | 25 ~ 75 | 8 | Φ 1000 | 160 | |||||

ZDS44 | 40 ~ 95 | 10 | Φ 1200 | 200 | |||||

ZDS45 | 60 ~ 140 | 15 | Φ 1400 | 280 | |||||

ZDS46 | 90 ~ 185 | 20 | Φ 1600 | 315 | |||||

ZDS47 | 110 ~ 235 | 25 | Φ 1750 | 400 | |||||

ZDS48 | 120 ~ 280 | 30 | Φ 1900 | 450 | |||||

ZDS49 | 150 ~ 325 | 35 | Φ 2050 | 500 | |||||

ZDS50 | 170 ~ 375 | 40 | Φ 2200 | 560 | |||||