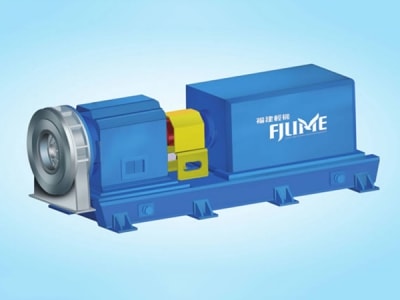

Fiber Separator, ZSF Series

Fiber Separator, ZSF Series

The ZSF series fiber separator is mainly used for separating long and short fiber during pulp screening. It can also be used as pulp screening equipment by controlling the rate of discharging rejects. Under the pressure, the stock enters into the screen cylinder along the tangential direction from the bottom. The heavy impurities are discharged from the collecting box of heavy impurities on the bottom of the fiber separator so as to prevent the rotor and screen basket from wearing and being damaged.

The stock flows into the screening zone of fiber separator. Affected by different pressure between the inner and outer of screen basket as well as moving energy, short fiber flows into the accept zone through screen slot. Affected by the self-washing created by the rotating of the rotor, the long fiber and light impurities held up by screen basket are discharged through the outlet at the top of the screen, which results in separating the long and short fibers as well as improving the efficiency of screening.

The advantage of fiber separator is to adopt the new design of sword-shaped rotor for saving energy. The new rotor structure is developed with application of fluid dynamics theory. 3D structure of rotor blades strengthens turbulence inside screen to promote rejects discharging efficiency, as well as to avoid pulp thickening. It also slows down linear speed of rotor to achieve high capacity.

| Model | Max. Capacity (t/24h) | Design Consistency (%) | Slot Size (mm) | Motor Power (KW) |

ZSF52 | 30 ~ 50 | 2.5 | 0.15 ~ 0.25 | 30 |

ZSF53 | 40 ~ 70 | 37 | ||

ZSF54 | 50 ~ 85 | 45 | ||

ZSF55 | 60 ~ 105 | 55 | ||

ZSF56 | 75 ~ 130 | 75 | ||

ZSF57 | 100 ~ 175 | 90 | ||

ZSF58 | 130 ~ 220 | 110 | ||

ZSF59 | 155 ~ 265 | 132 | ||

ZSF60 | 180 ~ 305 | 160 | ||

ZSF61 | 210 ~ 350 | 185 | ||

ZSF62 | 235 ~ 395 | 200 | ||

ZSF63 | 260 ~ 440 | 220 | ||

ZSF64 | 310 ~ 530 | 280 | ||

ZSF65 | 365 ~ 615 | 315 |