As a paper pulping machine manufacturer with over 50 years history, FUJIAN LIGHT INDUSTRY MACHINERY & EQUIPMENT CO., LTD. (FJLIME) has been ISO9001, ISO14001 certified, and has gained many patents. We can now provide markets with a complete set of equipment systems to process 300,000 tons of wastepaper and OCC pulp as well as 150,000 tons of deinked wastepaper stock annually.

Project Consultation

We are undertaking the project of pulping and paper making equipment. Please contact us if you're interested.

Pulping and Paper Making Engineering

-

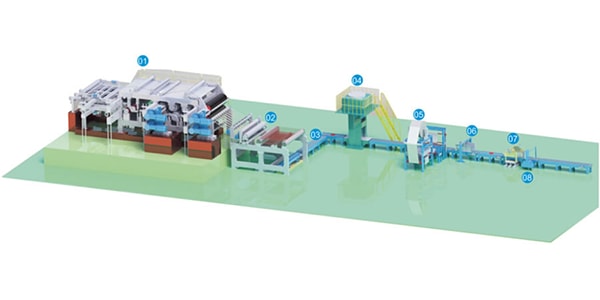

- Wet Lap/Pulp Baling System The wet lap or pulp baling system is used for the treatment of paper pulp with dryness of approximately 35% to 55%. For short-distance convenient transportation, the liquid paper pulp is dehydrated into wet pulp by a thickener or pulp extruder so as to formulate wet lap for use in our factory or the nearby paper factory without pulping system. Read More

-

- Pulp Drying System Due to the short storage time of the pulp, it can’t withstand long-distance transport. We have designed and developed pulp dry system to solve these problem. After the flash drying, the dry pulp block can be stored for a long time, which solves the problem that the wet pulp sheet only can be stored for short time or the pulp would be deteriorated over a period of time. Read More

-

- Newly Designed High-Speed Tissue Making Line with Energy-Saving Deinking System The newly developed high-speed Tissue Making Line with Energy-Saving Deinking System adopts innovative design. Our pulp mill machinery has the productivity as high as 600m/min, with the assurance in optimal operating stability and qualified output. The toilet paper produced maintains the same tensile force as that from regular paper making machine. Read More

-

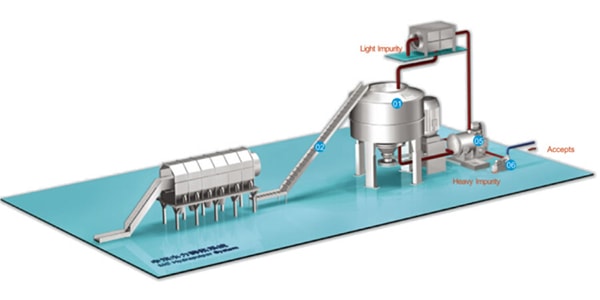

- H.C. Pulping System The H.C. pulping system consists of H.C. hydrapulper, impurity separator and drum screen. This high consistency pulper is a crucial device for waste paper deinking process. With the combined action of physical and chemical force, it allows newspaper, book paper, magazine paper, pictorial paper, composite paper and other white waste paper to be decomposed into fiber. Read More

-

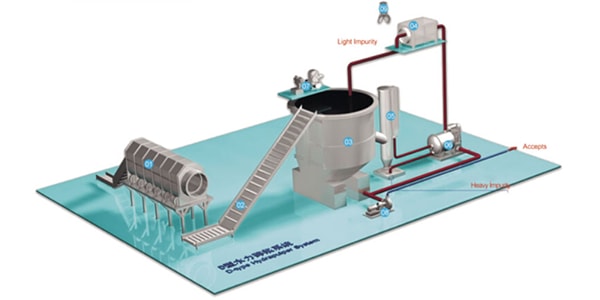

- D-Type Pulping System This hydrapulper system is used for breaking recycled cartons and other waste paper as well as removing impurities. The main features of D-type pulping system are the use of D-type vat and energy-saving Vokes rotor to make the contact between recycled paper and rotor more quickly and frequently. Compared with the traditional hydrapulper, it could shorten the time of pulp breaking and increase productivity without increasing the volume and power. Read More

-

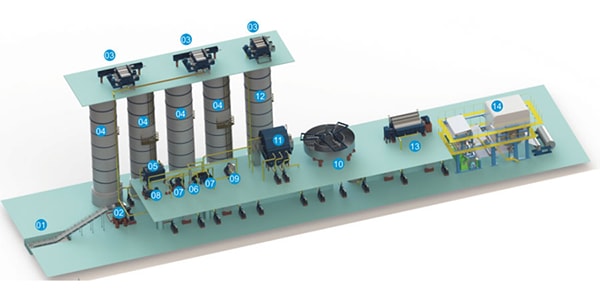

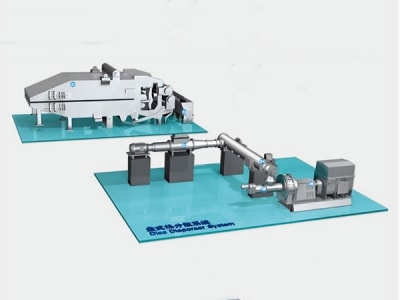

- Disc Disperse System The disc disperse system is widely used in the waste paper recycling and paper making fields.

The disc disperse system is designed with flexible inlet and outlet connection. The machine features good function of dispersing and can improve the quality of pulp. Read More

-

- Pulp Molded Product Making System The manufacturing process of our pulp molded product making system is generally classified into pulping, moulding, drying, and hot-press shaping. Taking waste newspaper, carton, presswork, and leftover bits and pieces from paper product factory as raw material, pulp in fixed concentration is obtained with the employment of pulper, filtrating device, and water injection equipment. Read More

-

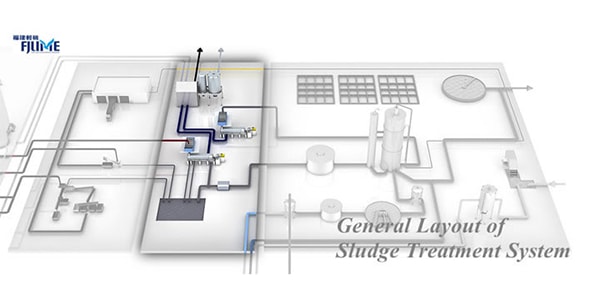

- Sludge Handling System During pulping and paper making, large amount of sludge is generated from mechanical filtration and chemical treatment. At this moment, sewage treatment system or sludge dewatering system is of great importance to the paper making plant. Read More