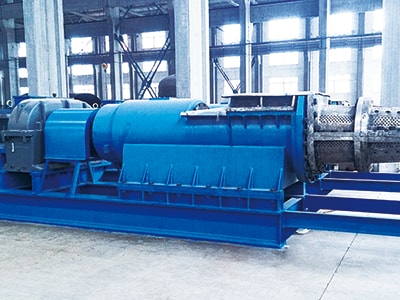

Cylinder Wire Thickener, ZNW Series

Cylinder Wire Thickener, ZNW Series

This series of cylinder wire thickener is crucial for the concentration and washing of low-consistency pulp in the papermaking process. It operates with an inlet pulp consistency of 0.5% to 1% and can increase the consistency to between 4% and 6% depending on the type of pulp being processed.

Features

- The thickening of the pulp primarily occurs through the differential liquid levels inside and outside the cylinder, complemented by the pressing action between the pressure roller and the cylinder to de-water and thicken the pulp effectively.

- The cylinder is the main component of the thickener, consisting of end and middle ring frames, a filter mesh, and a central shaft. The filter mesh, typically made from perforated steel plates or high-density polyethylene, is fitted with a suitable mesh cloth for operation.

- Equipped with a pressure roller and a doctor blade, the thickener's pressure roller is supported on the side of the mesh and driven by the cylinder. The roller is coated with rubber, and its surface hardness is between 60-65 Shore hardness. The pressure of the roller can be adjusted manually, and it comes with a scraper blade that closely aligns with the roller to peel off the pulp layer efficiently.

- When operating the thickener, it's essential to maintain stable pulp levels to prevent overflow and clogging. Also, ensure that the sealing strips are tightly secured to facilitate effective pulp concentration.

| Model | ZNW2 | ZNW3 | ZNW4 | ZNW5 | ZNW5A | ZNW6 | ZNW7 | ZNW8 | ZNW9 |

| Capacity(T/d) | 5-10 | 8-20 | 15-35 | 20-50 | 25-60 | 30-75 | 35-90 | 40-100 | 45-120 |

| Wire Area(㎡) | 5 | 8 | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

| Wire Mould Size (Mm) | Φ1000x1800 | Φ1250x2000 | Φ1500x3000 | Φ1000x1800 | Φ1000x1800 | Φ2500x3800 | Φ2500x4400 | Φ3000x4000 | Φ3000x4600 |

| Inlet Consistency (%) | 0.5-1 | ||||||||

| Outlet Consistency (%) | 5-6 | ||||||||

| Motor Power (KW) | 4 | 5.5 | 7.5 | 11 | 11 | 11 | 15 | 18.5 | 18.5 |

Related Products

Get in Touch