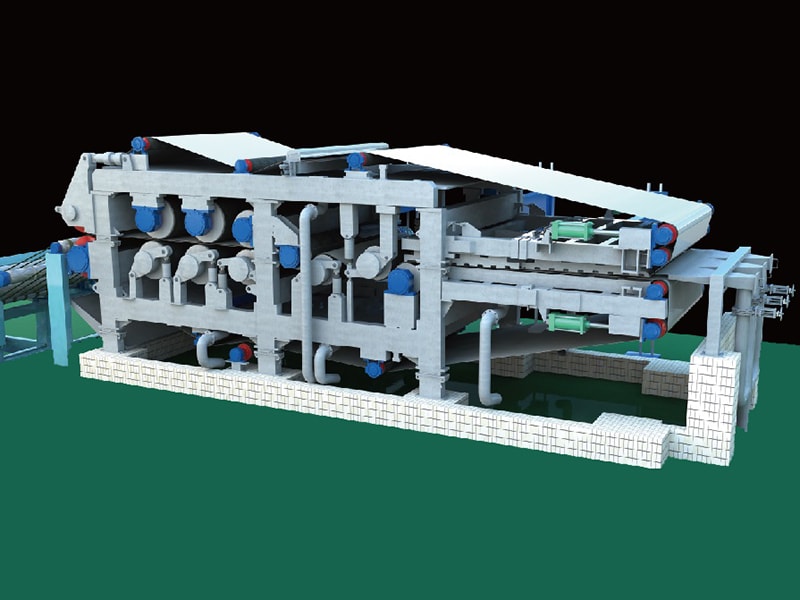

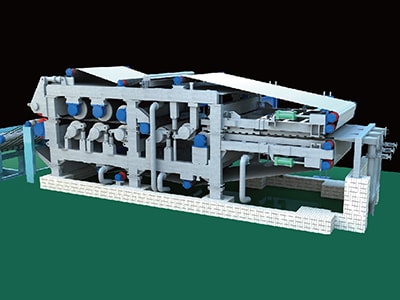

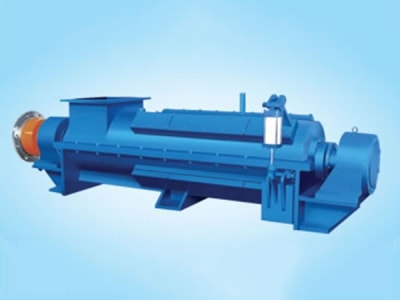

Twin-Wire Press Washer

Twin-Wire Press Washer

The twin-wire press washer is mainly used to wash and thicken various kinds of pulp in the pulping and papermaking process.

Features

The twin-wire press washer features lengthened pressure section, increased pressure difference, higher thickening ratio and stable outlet consistency (28% to 32%). The wedge-shaped dewatering filter plate and double pressing roll unit combine to dewater, giving the press washer the advantages of little loss of fibers and low energy consumption.

Specifications of Twin-Wire Press Washer

| Model | ZNS1 | ZNS2 | ZNS3 | ZNS4 | ZNS4A | ZNS5 | ZNS6 |

| Capacity (t/24h) | 30~50 | 50~100 | 75~150 | 100~200 | 130~250 | 150~300 | 180~350 |

| Working width(mm) | 800 | 1200 | 1800 | 2400 | 2600 | 2800 | 3200 |

| Inlet Consistency(%) | 3~5 | ||||||

| Inlet Pressure (MPa) | 0.01~0.03 | ||||||

| Outlet Consistency(%) | 28~35 | ||||||

| Wire Speed(m/min) | 9~30 | ||||||

| Working Pressure(MPa) | 0.4~0.7 | ||||||

| Water Pressure(MPa) | 1.0~1.5 | ||||||

| Motor Power (kw) | 11×2 | 15×2 | 22×2 | 30×2 | 30×2 | 30×2 | 37×2 |

| Size(L×W×H) | 7780×3800 ×2780 | 7780×4200 ×2780 | 7780×4800 ×2780 | 7810×5500 ×2820 | 7810×5690 ×2820 | 7810×5890 ×2820 | 7900×6500 ×2880 |

Related Products

Get in Touch

Other Products