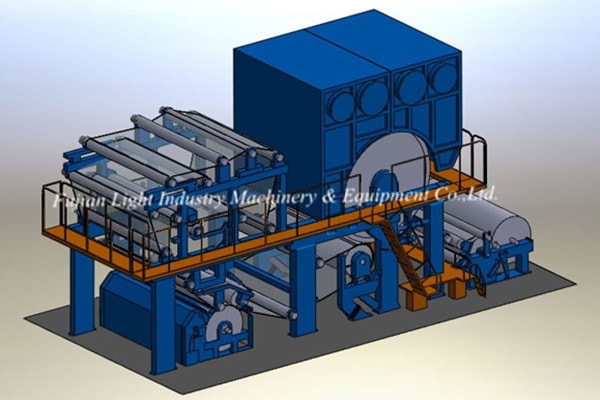

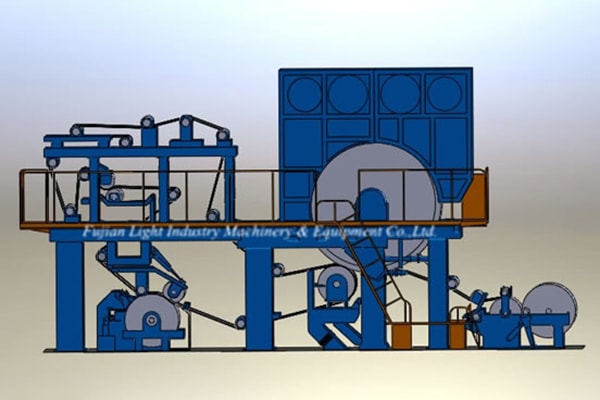

The newly developed high-speed Tissue Making Line with Energy-Saving Deinking System adopts innovative design. Our pulp mill machinery has the productivity as high as 600m/min, with the assurance in optimal operating stability and qualified output. The toilet paper produced maintains the same tensile force as that from regular paper making machine.

Features

- The productivity of the high speed paper making machine is improved from 300m/min to 500-600m/min with the employment of vacuum cylinder mold.

- Besides, the headbox increases the vertical and horizontal paper tensile force from 1:2 to 1:1.

- Vacuum carrier roller is adopted for the drying cylinder.

- The utilization of special dryer hood enhances the water evaporation uniformity and drying speed.

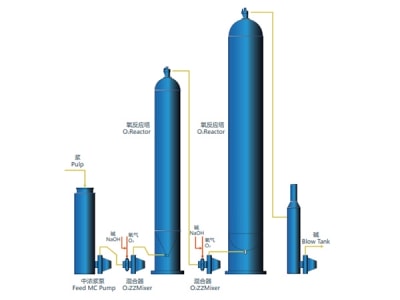

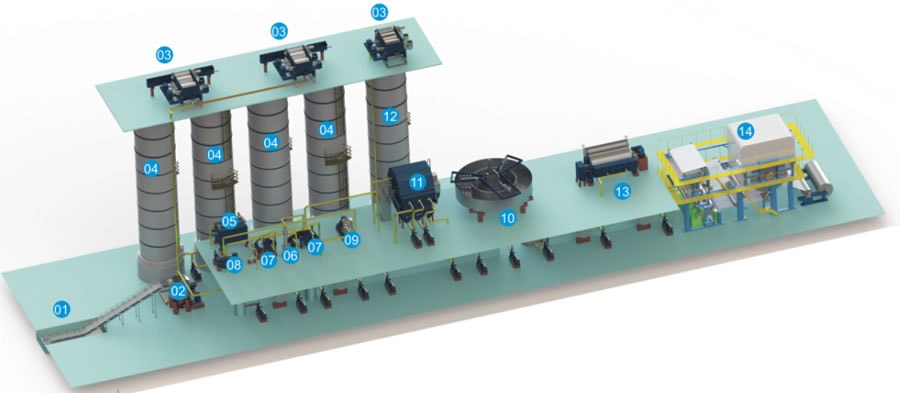

System Components

- Chain Conveyor

- Vertical Hydrapulper

- Double Cylinder Pulp Press

- Soaking Tower

- Drum Screen

- H.C. Cleaner

- Fiber Separator (Slot Type)

- Self-Cleaning Vibration Screen

- M.C. Pressure Screen (Slot Type)

- High-Efficiency Shallow Flotation Cell

- Vacuum Multi-Disc Washer Without Water Leg

- Sterilizing Tower

- Round-Wire Thickener

- Tissue Paper Machine