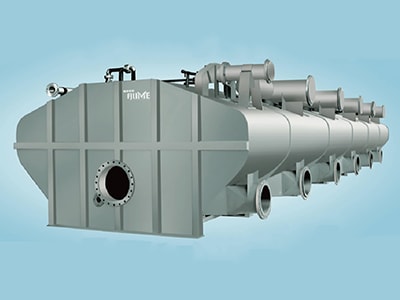

Impurity Separator

Impurity Separator

ZDF series impurity separator is a product that greatly simplifies pulping process for low power consumption. It is widely used in waste paper recycling and paper making fields, and is increasingly popular with customers from Panama, Ecuador, Peru, Indonesia, among other countries.

Application

Our impurity separator is designed to defiberize stock and separate impurities from fibers. It is used after pulper to separate light and heavy impurities in the pulp and further defiberize the paper.

Structure and Features

- The impurity separator consists of steel vat, horizontal rotor separator, drive mechanism and inlet pipe.

- Thanks to the weir board inside the separator, heavy impurities deposit in the bottom while the stock and light impurities enter the circulation zone to be further screened. When the impeller rotates, the stock is suctioned axially and ejected at high speed from the periphery of the impeller. In this way, the turbulence circulation is intensified.

- By adjusting the weir and the clearance between the impeller and screen plate, the quality and quantity of the pulp can be controlled.

- The separator can work together with pulper to remove light and heavy impurities, improving the production capacity of the pulping machine.

Specifications of Impurity Separator

| Model | Production amount (m3/h) | Rotor diameter (mm) | Screen hole diameter(mm) | Stock consistency(%) | Motor power(KW) |

ZDF31 | 100~150 | Ф750 | Ф4~Ф12 | 2.5~5 | 30 |

ZDF32 | 200~300 | Ф910 | 45 | ||

ZDF33 | 400~500 | Ф1050 | 55 | ||

ZDF34 | 600~700 | Ф1200 | 75 | ||

ZDF35 | 800~900 | Ф1350 | 110 | ||

ZDF36 | 1000~1100 | Ф1500 | 132 | ||

ZDF37 | 1200~1300 | Ф1650 | 160 | ||

ZDF41 | 30~50 | Ф550 | Ф6~Ф14 | 2.5~5 | 30 |

ZDF42 | 60~80 | Ф700 | 55 | ||

ZDF43 | 120~150 | Ф800 | 75 | ||

ZDF44 | 180~210 | Ф900 | 90 | ||

ZDF45 | 220~250 | Ф1000 | 110 | ||

ZDF46 | 270~300 | Ф1100 | 132 |

Related Products

Get in Touch