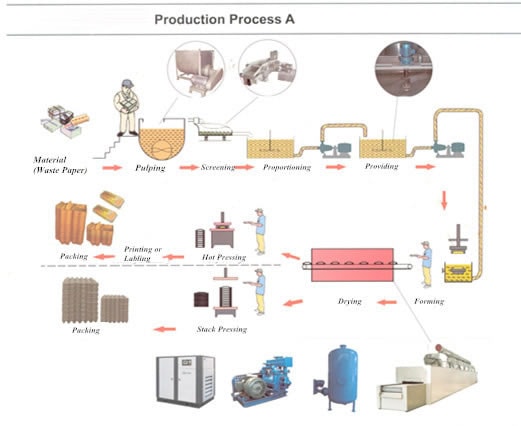

The manufacturing process of our pulp molded product making system is generally classified into pulping, moulding, drying, and hot-press shaping. Taking waste newspaper, carton, presswork, and leftover bits and pieces from paper product factory as raw material, pulp in fixed concentration is obtained with the employment of pulper, filtrating device, and water injection equipment.

On the tailor-made metal mold for the egg tray manufacturing equipment, wet mold is produced through vacuum absorption. Then, the semi-finished paper product shall be dried and finally shaped via hot pressing.

The pulp molded product making system is applicable for manufacturing the product in simple structure, including, egg trays/cartons, cup carriers, disposable medical-care products and other industrial packages.

With valuable experience in the industry, we specifically develop equipment and technology based on up-to-date development tendency. Our molded pulp packaging production line is characterized by stable operation, prominent efficiency, and energy conservation.